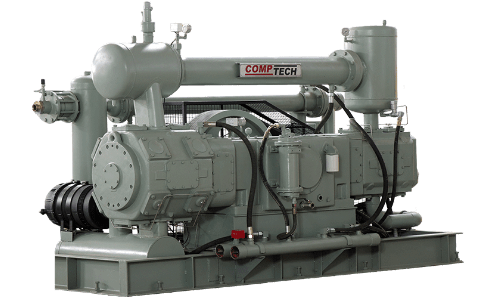

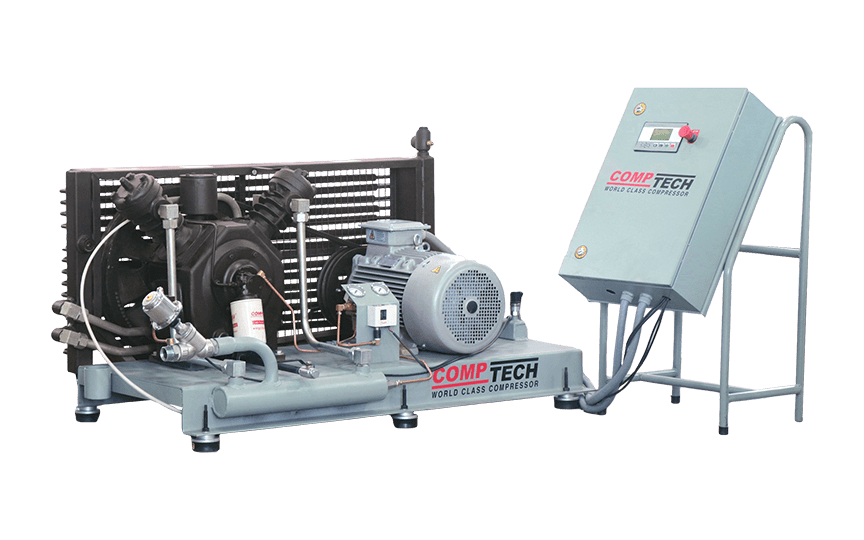

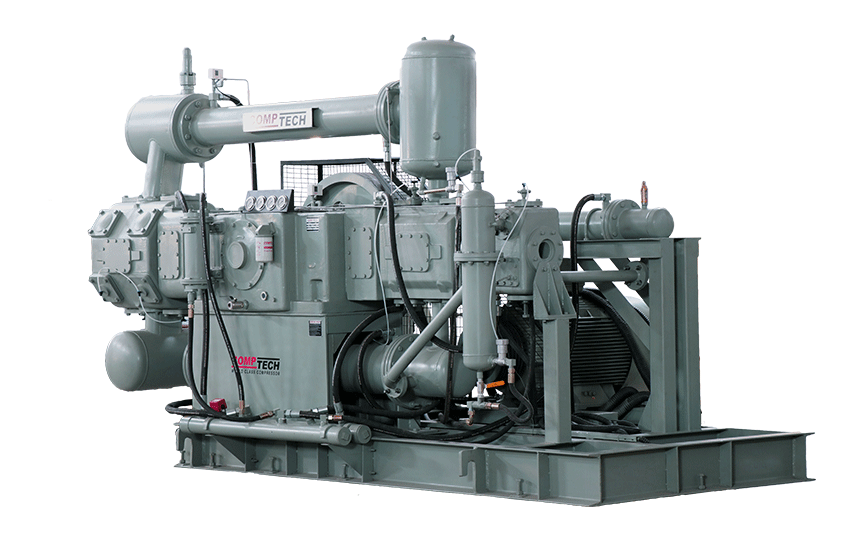

High Pressure Oil Free

Air Compressor

Our Oil Free Compressor have low rpm & rugged cast iron design ideal for heavy duty continuous 24 x 7 operating year after year. Forged Crank Shaft & Connecting Rod, Precision Main & Crank Pin Bearings with force feed lubrication have very high load bearing capacity & hardly needs replacements. Two throw balance-opposed frame, designed to minimize unbalanced forces.

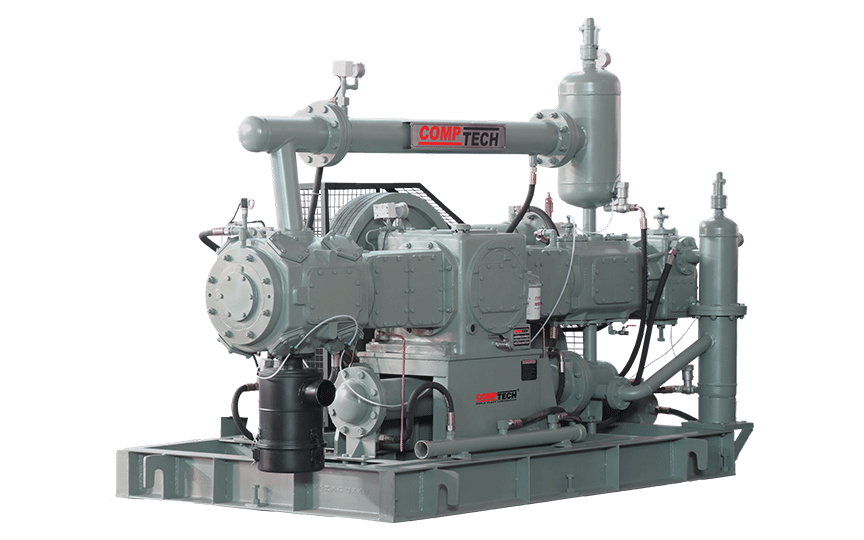

Why Comptech Oil Free High Pressure Air Compressor?

100% oil free air

Vibration free quieter operation

Sustainable design for decades

Service friendly design

Lowest area occupancy

Advance plc for easy operation

Premium efficiency IE3 motor

Lowest life cycle cost

Specification

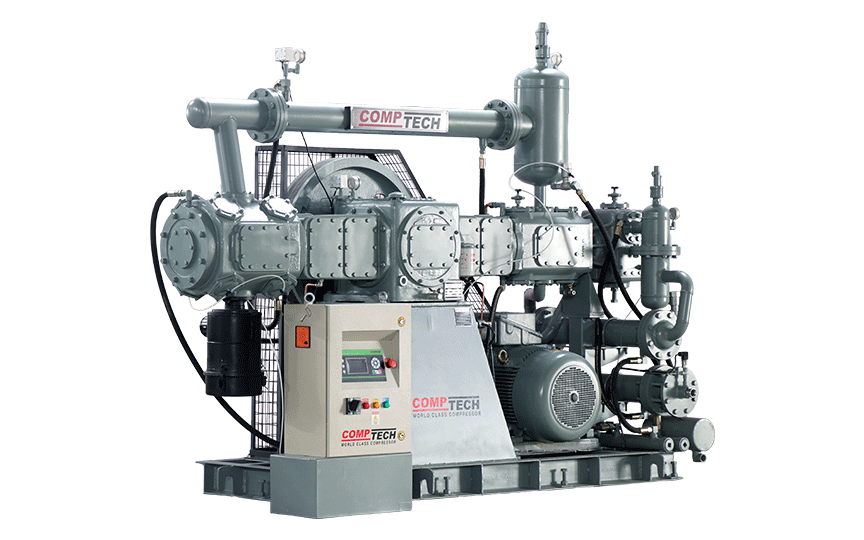

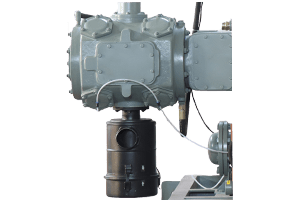

Slient Design Intake Filter

CTBO series inlet filters are amongst the largest on the market for comparable flow-rates. What’s more, they are super-silenced and firmly mounted and their dust filtration level is up to an impressive 3 microns.

Benefits: Lower noise and Better Efficiency

Low Vibration

Each CTBO Series Compressor is properly balanced, which leads to lowest vibrations in its class. Also, High quality vibration pads are used which are distributed in a calculated manner.

Benefits: Lowest Vibrations, Better life & No Foundation Requiremnt.

IE3 Premium Efficiency Motor

Comptech uses Best in Class Premium Efficiency IE3 Motor to enhance the

Performance and Energy Savings.

Benefits: Energy Saving of up to 2%.

High Efficiency Valves

Premium quality Valve assembly designed to last long which requires Annual one time maintenance only, without losing its efficiency.

Benefits: Better Efficiency and Greater Life.

Piston & Piston Rings

Highly self lubricated PTFE Piston ring, rider ring and Piston and rod packing rings, specially developed to deliver highly efficient Guaranteed 100% Oil Free Air.

Benefits: 100% Oil Free Air.

Smart Control PLC

The Smart Control Advanced microprocessor based system with a color screen display all the necessary details, Such as live pressure, temperature, current measurement, maintenance indications and all the safety settings with faults history.

Benefits: Easy and Simple Operations.

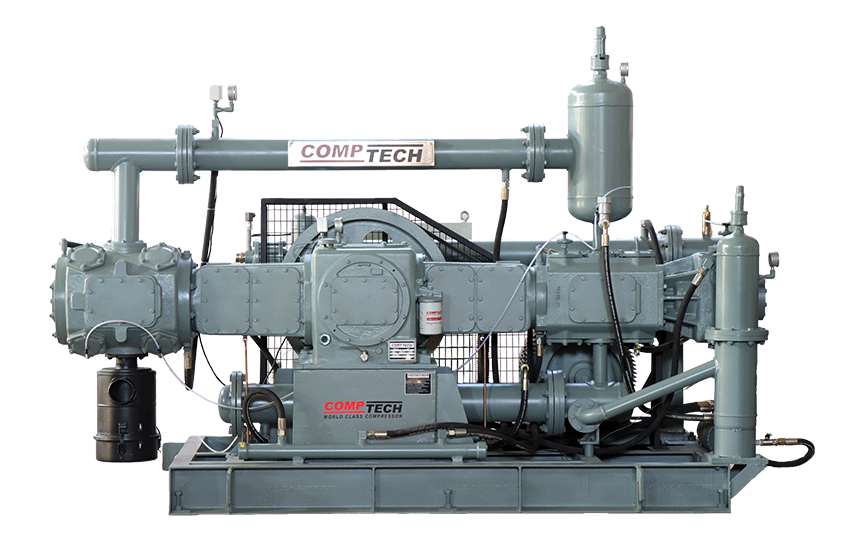

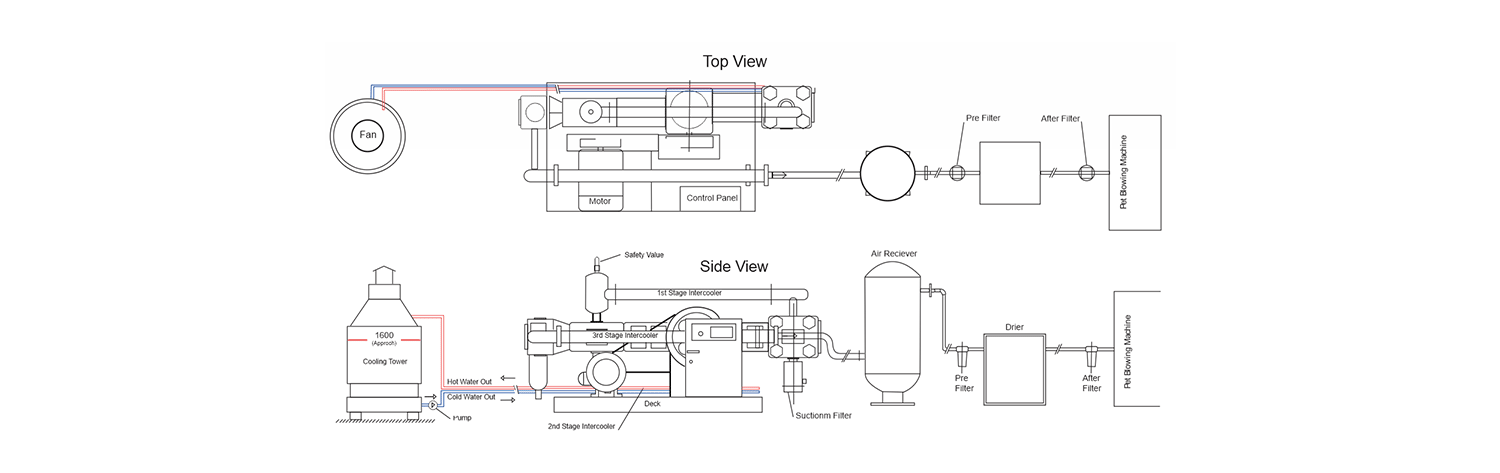

Typical Air Supply System

Air boosters take pre-compressed air from an existing network (your plant air system) or from a low-pressure compressor and increase it to the required higher pressure. A CompTech Air Booster is a specially designed reciprocating compressor that accepts elevated inlet pressures of 10 kg/cm² and boosts that pressure up as far as 40 kg/cm².

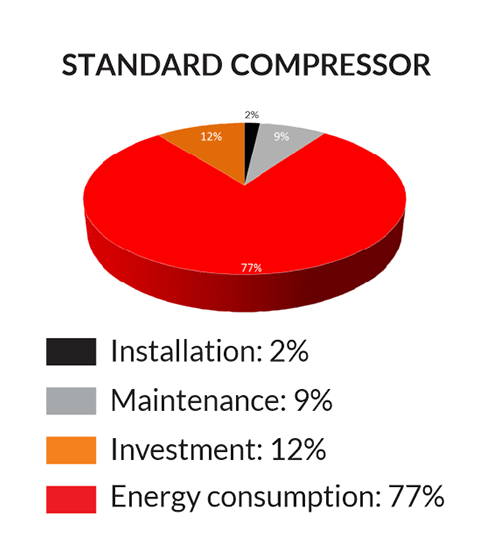

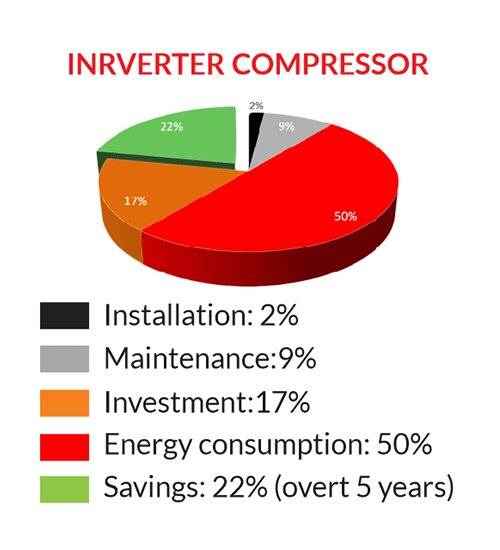

Power Saving with VSD

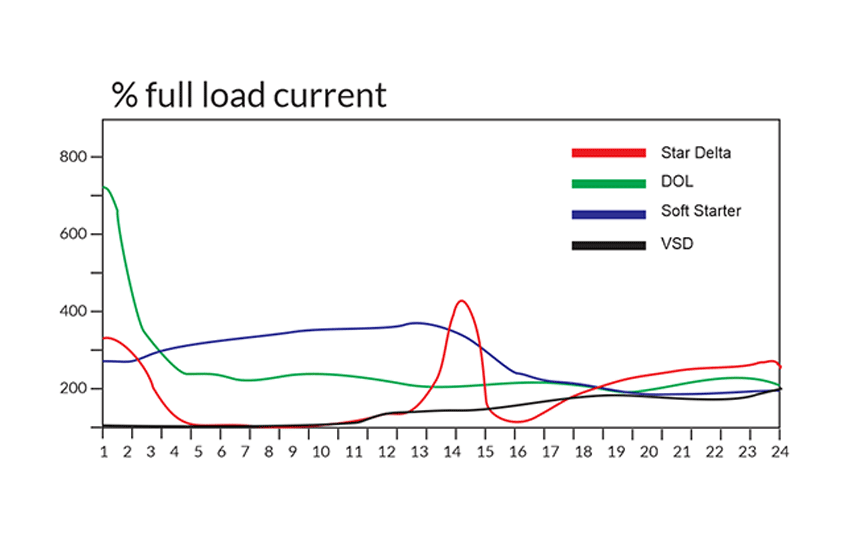

Low Starting Current

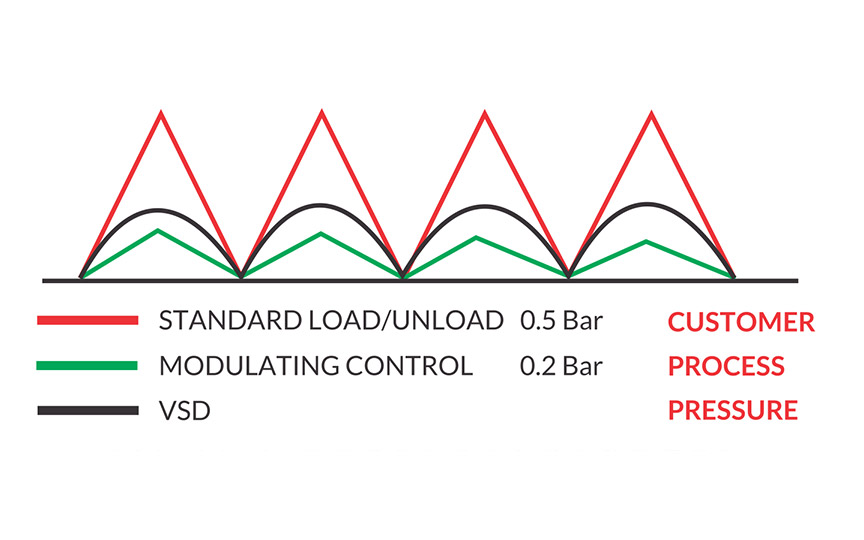

Constant Outlet Pressure

Low Maintenance

High Savings Under Fluctuating Requirement

VSD ensures there will be no high current peak at the startup, as current increases gradually, which eliminates the use of heavy equipments to withstand the peaks.

Because of the narrow pressure band, the consumption at the peaks are omitted in comparison with Star Delta controls. This reduces energy consumption and provides a stable pressure.

Due to VSD, the average RPM of the compressor also reduces, which means lesser wear & tear and results into less maintenance

During Low requirement, VSD reduces the speed of motor resulting in low energy consumption. The compressor will consume just the energy for the required air it produces.

Power Saving with VFD