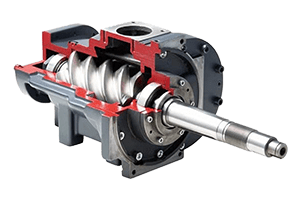

Rotary Screw

Air Compressor TWO STAGE

CTS II – Series, a 2 Stage Screw Air Compressor Series to enhance the profitability of your production. The regulated speed models or VFD+ models save energy by matching the output to the plant air demand with an added advantage of High Efficiency internal Permanent Magnet Motors to ensure you do not lose out on efficiency anywhere.

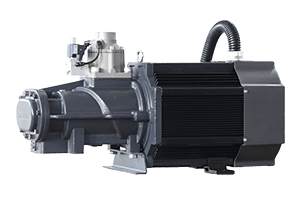

Energy Saving 1:1 Direct Drive

1:1 Direct drive is maintenance free coupling, which reduces number of components needed in gear drive, increasing reliability and durability through elimination of wear & transmission loss.

Air & Oil Cooler

Based on the Hot Climate of India, we provide Big size, high efficient Air & Oil Cooler which increases the durability of the Compressor

PLC

Advanced microprocessor based control system with features such as online pressure, temperature and current measurement, safety settings, online maintenance indications. It also has a unique fan control system which eliminates use of thermostats in the compressor

High Capacity Dual Air Filtration

Big Size, High efficient , dual filtering stage suction Air Filter for Dusty Environment of India with prefilters.

Oil Seperation System

Two stage oil seperation system in which Oil is initially separated by Centrifugal force and minimal oil remains are then separated by separator element.

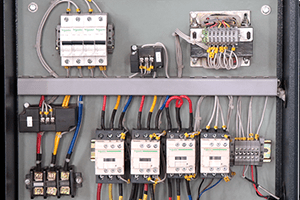

Control Panel

Control Panel / starter has been put in the cold zone which ensure long life operation. Switchgears are also made of Siemens or standard quality.

Seamless Pipelines

We use Seamless, long life Pipelines instead of short-lived Hosepipes, which eliminates oil Leakages.

Single Shaft Design

Our single shaft design have maintenance free coupling, which reduces number of

components needed in gear drive, increasing reliability & durability through elimination of wear & transmission loss.

Oil Filtration System

High efficiency two stage oil filtration system in which oil is initially separated by Centrifugal force and minimal oil remains are then separated by separator element.

Technical Specifications

| COMPRESSOR MODEL | MOTOR | FAD @ 8 kg/cm² | SOUND LEVEL | COMPRESSOR | |

|---|---|---|---|---|---|

| kw | HP | CFM | DB | rpm | |

| CTS II 8-30 | 22 | 30 | 145 | 72 | 1450 |

| CTS II 8-40 | 30 | 40 | 215 | 72 | 1450 |

| CTS II 8-50 | 37 | 50 | 258 | 73 | 1450 |

| CTS II 8-60 | 45 | 60 | 352 | 74 | 1450 |

| CTS II 8-75 | 55 | 75 | 405 | 75 | 1450 |

| CTS II 8-100 | 75 | 100 | 565 | 76 | 1450 |

| CTS II 8-120 | 90 | 120 | 706 | 76 | 1450 |

| CTS II 8-150 | 110 | 150 | 812 | 76 | 1450 |

| CTS II 8-180 | 132 | 180 | 990 | 76 | 1450 |