AIR Booster Air Compressor

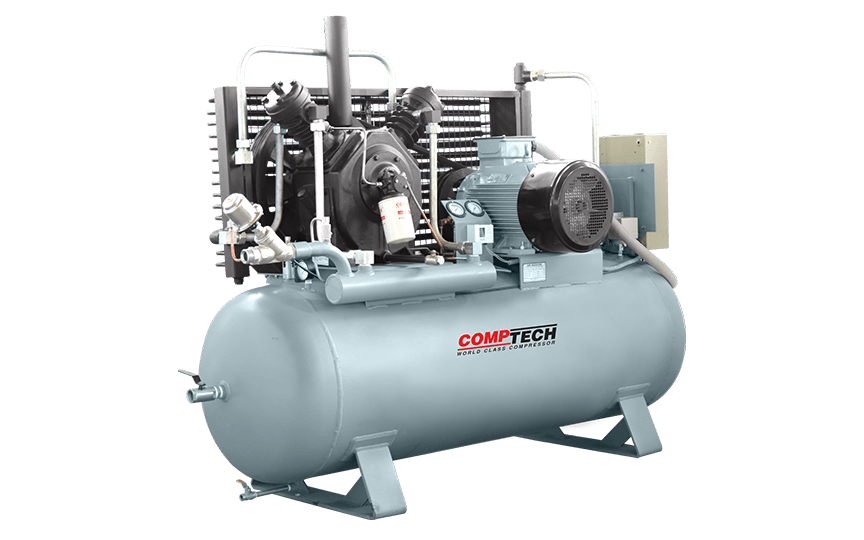

Our Air Booster Compressor comes with robust design which gives you maximum output. Advanced microprocessor based control system with features such as online pressure, safety settings, online maintenance indications. Heavy duty air cooled after cooler for efficient cooling eliminates cooling tower requirement.

Why Comptech AIR Booster?

Piston Ring

Imported Piston Rings with long life. Highly efficient.

Crank Case

Strong and robust crank case is made of high grade cast iron.

Valves

Concentric ring type valves with imported stainless steel material.

Force Feed Lubrication

A forced feed lubrication system increased reliability & service life,

Cylinder

Cylinders are bored with super precision that ensures less oil consumption.

PLC

Advanced microprocessor based control system.

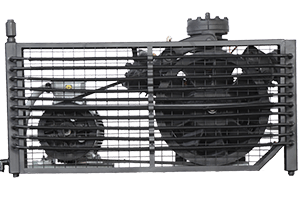

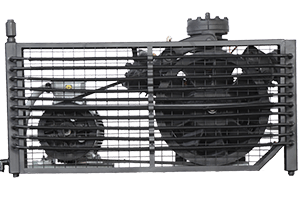

Air Cooled After Cooler

Heavy duty air cooled after cooler for efficient cooling eliminates cooling tower requirement.

Piston Ring

Imported Piston Rings with long life. Highly efficient.

Crank Case

Strong and robust crank case is made of high grade cast iron. Splash lubrication system ensures proper circulation of oil to all parts of the rotating system.

Valves

Concentric ring type valves with imported stainless steel material.

Force Feed Lubrication

A forced feed lubrication system provides increased reliability & service life, Oil filtration system extends the oil & Booster life.

Cylinder

Cylinders are bored with super precision and finished by a special process that ensures minimum oil consumption and negligible wear for great durability.

PLC

Advanced microprocessor based control system with features such as online pressure, temperature and current measurement, safety settings, online maintenance indications. It also has a unique fan control system which eliminates use of thermostats in the compressor.

Air Cooled After Cooler

Heavy duty air cooled after cooler for efficient cooling eliminates cooling tower requirement.

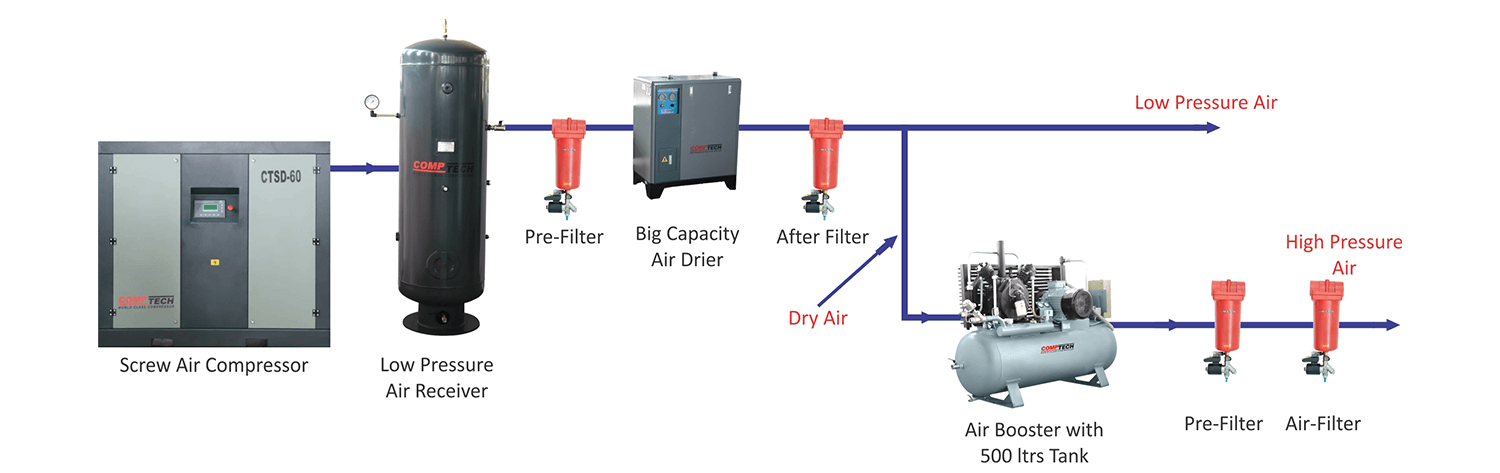

Typical Air Supply System

Air boosters take pre-compressed air from an existing network (your plant air system) or from a low-pressure compressor and increase it to the required higher pressure. A CompTech Air Booster is a specially designed reciprocating compressor that accepts elevated inlet pressures of 10 kg/cm² and boosts that pressure up as far as 40 kg/cm².

Technical Specifications

| COMPRESSOR MODEL | MOTOR | FAD @ 8 kg/cm² | FAD @ 10 kg/cm² | SOUND LEVEL | COMPRESSOR RPM | DIMENSION LWH | WEIGHT | |

|---|---|---|---|---|---|---|---|---|

| kw | HP | CFM | CFM | DB | INCHES | KG. | ||

| CTSD 25 | 18.5 | 25 | 110 | 100 | 71 | 2900 | 49 X 30 X 51 | 550 |

| CTSD 30 | 22 | 30 | 135 | 114 | 72 | 2900 | 49 X 30 X 51 | 550 |

| CTSD 40 | 30 | 40 | 185 | 172 | 72 | 2900 | 57 X 35 X 58 | 750 |

| CTSD 50 | 37 | 50 | 232 | 215 | 73 | 2900 | 57 X 35 X 58 | 800 |

| CTSD 60 | 45 | 60 | 275 | 254 | 74 | 2900 | 73 X 42 X 67 | 960 |

| CTSD 75 | 55 | 75 | 356 | 321 | 75 | 2900 | 73 X 42 X 67 | 1150 |

| CTSD 100 | 75 | 100 | 490 | 450 | 76 | 2900 | 79 X 47 X 65 | 1400 |

| COMPRESSOR MODEL | MOTOR | NO OF CYLINDER | FAD @10 kg/cm².g | MAX.WORKING PRESSURE | |

|---|---|---|---|---|---|

| kw | HP | INLET PRESSURE | (kg/cm².g) | ||

| CTB-10 | 7.5 | 10 | 2 | 85 | 40 |

| CTB-12 | 9 | 10 | 2 | 92 | 40 |

| CTB-15 | 11 | 15 | 2 | 110 | 40 |

| CTB-20 | 15 | 20 | 2 | 150 | 40 |

| CTB-25 | 18.5 | 25 | 2 | 200 | 40 |

| CTB-30 | 22 | 30 | 3 | 225 | 40 |