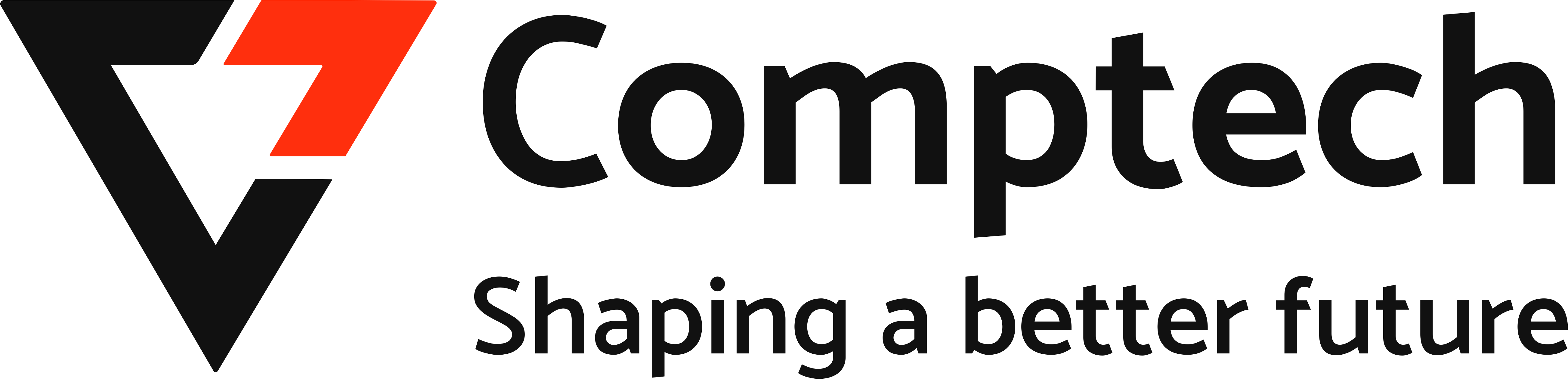

OIL FREE

MEDIUM PRESSURE

Oil Free Medium Pressure have Forged Crank Shaft & Connecting Rod, Precision Main & Crank Pin Bearings with force feed lubrication have very high load bearing capacity & hardly needs replacements. Low RPM & rugged cast iron design ideal for heavy duty continuous 24 x 7 operating year after year. Cylinders constructed with large cast in water jackets & specially designed intercoolers for dimensional stability & better cooling under continuous operation.

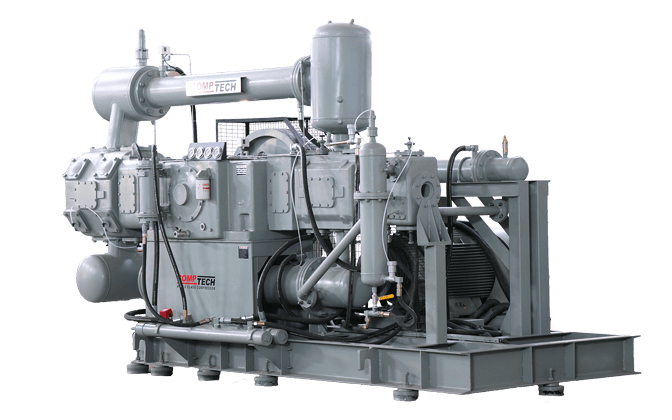

Slient Design Intake Filter

CTBO series inlet filters are amongst the largest on the market for comparable flow-rates. What’s more, they are super-silenced and firmly mounted and their dust filtration level is up to an impressive 3 microns.

Low Vibration

CTBO Series Compressors have the least vibrations, which leads to no foundation and cheap installation. Also, due to low Vibrations, the compressors get a longer life.

Premium Efficiency Motor

Best in Class High Efficiency IE3 Motor for

better performance and energy savings

High Efficiency Valves

Premium quality Valve assembly designed to last long which requires Annual one time maintenance only, without losing its efficiency.

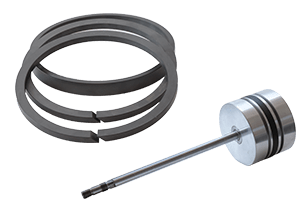

Piston & Piston Rings

Highly self lubricated PTFE Piston ring, rider ring and Piston and rod packing rings, specially developed to deliver highly efficient Guaranteed 100% Oil Free Air.

Smart Control PLC

The Smart Control Advanced microprocessor based system with a color screen display all the necessary details, Such as live pressure, temperature, current measurement, maintenance indications and all the safety settings with faults history.

Technical Specifications

Oil Free Medium Pressure

| COMPRESSOR MODEL | MOTOR HP | COMPRESSOR RPM | CFM | MAXIMUM PRESSURE | ||

|---|---|---|---|---|---|---|

| PD | FAD | Psig | Kg/cm2g | |||

| CTV 7 X 5 | 30 | 750 | 164 | 110 | 8.8 | 125 |

| CTV 8 X 5 | 40 | 750 | 215 | 143 | 7 | 100 |

| CTV 8 X 7 | 40 | 520 | 208 | 144 | 8.8 | 125 |

| CTV 8 X 7 | 50 | 650 | 260 | 180 | 8.8 | 125 |

| CTV 9 X 7 | 60 | 650 | 330 | 240 | 7.7 | 110 |

| CTV 11 X 7 | 60 | 520 | 398 | 255 | 7 | 100 |

| CTV 11 X 7 | 75 | 650 | 498 | 319 | 7 | 100 |

Vertical Models (Single Stage)

| COMPRESSOR MODEL | MOTOR HP | FAD CFM at 7 Kg/ cm² | FAD CFM at 9 Kg/ cm² |

|---|---|---|---|

| CTV 10 – 15 P | 15 | 60 | 43 |

| CTV 09 – 20 P | 20 | 85 | 70 |

| CTV 09 – 25 P | 25 | 112 | 94 |

| CTV 09 – 30 P | 30 | 135 | 111 |

Horizontal Two Stage High Pressure Balanced Opposed Models

| COMPRESSOR MODEL | MOTOR HP | FAD CFM at 12 Kg/ cm² | FAD CFM at 15 Kg/ cm² |

|---|---|---|---|

| CTBO 4 – 40 P | 40 | 150 | 145 |

| CTBO 4 – 75 P | 75 | 297 | 277 |

| CTBO 4 – 100 P | 100 | 415 | 399 |

| CTBO 4 – 150 P | 150 | 608 | 516 |

Horizontal Two Stage Balanced Opposed Models

| COMPRESSOR MODEL | MOTOR HP | FAD CFM at 7 Kg/cm² | FAD CFM at 9 Kg/cm² |

|---|---|---|---|

| CTBO 10 – 40 P | 40 | 223 | 189 |

| CTBO 10 – 50 P | 50 | 273 | 214 |

| CTBO 10 – 60 P | 60 | 332 | 283 |

| CTBO 10 – 75 P | 75 | 415 | 324 |

| CTBO 10 – 100 P | 100 | 524 | 472 |

| CTBO 10 – 120 P | 120 | 644 | 576 |

| CTBO 10 – 150 P | 150 | 817 | 682 |

| CTBO 10 – 180 P | 180 | 922 | 819 |

| CTBO 10 – 215 P | 215 | 1182 | 955 |

Horizontal Two Cylinder Single Stage Balanced Opposed Models

| COMPRESSOR MODEL | MOTOR HP | FAD CFM at 2.5 Kg/cm² | FAD CFM at 4 Kg/cm² |

|---|---|---|---|

| CTBO 4 – 50 P | 50 | 420 | 332 |

| CTBO 4 – 60 P | 60 | 504 | 398 |

| CTBO 4 – 75 P | 75 | 625 | 495 |

| CTBO 4 – 100 P | 100 | 781 | 660 |

| CTBO 4 – 120 P | 120 | 1065 | 770 |

| CTBO 4 – 150 P | 150 | 1310 | 1022 |

| CTBO 4 – 180 P | 180 | 1645 | 1272 |

| CTBO 4 – 215 P | 215 | 1610 | 1430 |

NL Air Cooled Models

| COMPRESSOR MODEL | MOTOR HP | RPM | TANK | PISTON DISPLACEMEN CFM |

|---|---|---|---|---|

| 5T2NL | 7.5 | 600 | 300 LTR | 26.25 |

| 5T2NL | 10 | 930 | 300 LTR | 3 |

| 10T3NL | 12.50 | 592 | 500 LTR | 47.10 |

| 10T3NL | 15 | 633 | 500 LTR | 67.13 |

| 10T3NL | 20 | 844 | 500 LTR | 50 |